Bangladesh’s construction industry is experiencing a phenomenal surge. From towering skyscrapers to intricate architectural marvels, concrete reigns supreme as the building material of choice. But with this growth comes the constant quest for innovation and improvement. Enter PP fibers, a revolutionary material poised to disrupt the way concrete is reinforced. Pioneered in Bangladesh by Naif Engineering and Builders Ltd. (Top Construction Company in Bangladesh), PP fibers are ushering in a new era of lighter, stronger, and more versatile concrete structures.

Why Rethink Rebar, the Traditional King?

For generations, steel rebar has been the undisputed champion of concrete reinforcement. Its undeniable strength provides the backbone for countless structures. However, steel rebar also comes with limitations:

- Corrosion Concerns: Steel is susceptible to rust, especially in Bangladesh’s humid climate and coastal regions. This corrosion weakens the rebar and ultimately compromises the integrity of the concrete structure.

- Weighty Woes: Steel rebar’s bulky nature can be cumbersome for intricate designs or thin concrete applications. Constructing buildings with intricate architectural elements or delicate concrete features becomes a challenge.

- Design Dilemma: The inflexibility of steel rebar restricts design freedom. Creating aesthetically pleasing or innovative concrete structures becomes difficult with traditional rebar methods.

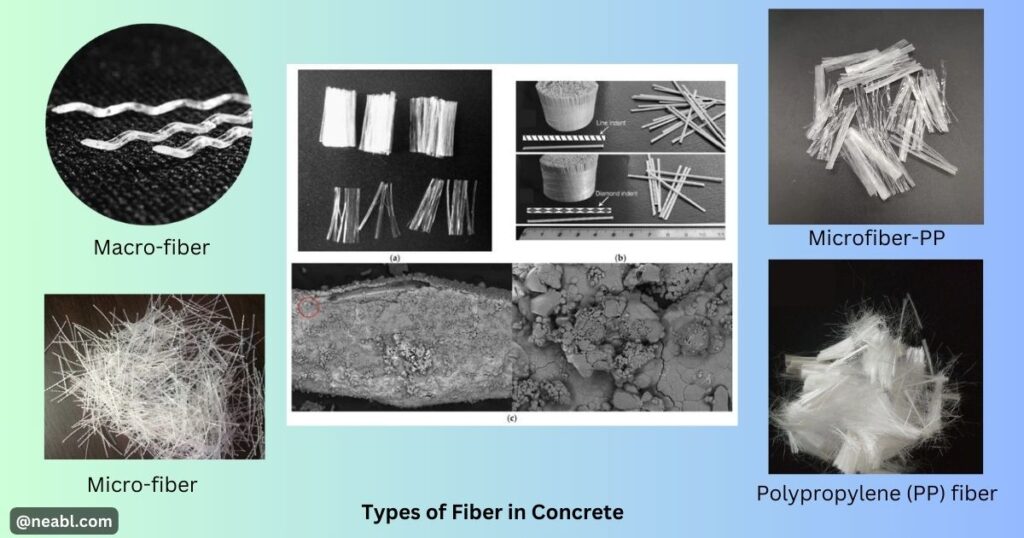

Types of Fiber in Concrete

While PP fibers are a game-changer, they are not the only fiber used in concrete reinforcement. Here’s a quick breakdown of some common types, alongside a helpful image for reference:

- Macro Fibers: These are the longest fibers used in concrete reinforcement, offering superior crack control and improved impact resistance. They are particularly effective in enhancing the flexural strength and toughness of hardened concrete.

- Micro Fibers: These are short, straight fibers primarily used to control plastic shrinkage cracks in fresh concrete. They are well-dispersed throughout the mix and help minimize the formation of cracks as the concrete sets.

- Microfiber-PP (Polypropylene): A specific type of microfiber made from polypropylene. They offer similar benefits to general microfibers but can also improve the overall crack control in hardened concrete due to their unique properties.

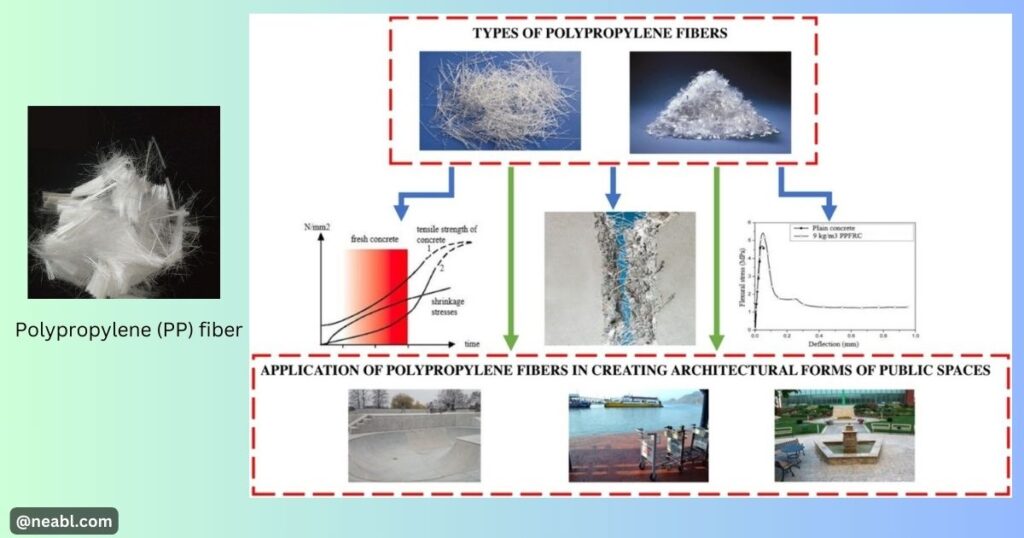

- Polypropylene (PP) Fiber: As discussed earlier, these are short, chopped fibers that provide good crack control and are a versatile option for various concrete applications. They come in different variations like monofilament (single, straight fibers) and fibrillated (tiny nets of PP fibers) to cater to specific needs.

PP Fibers: A Lightweight Champion Emerges

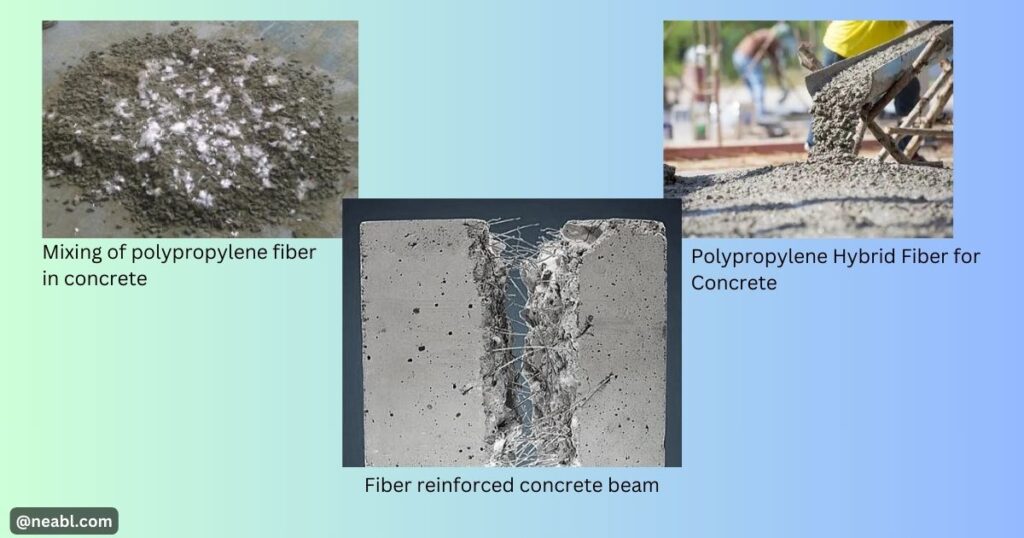

Naif Engineering and Builders Ltd. is at the forefront of a new wave of construction technology by introducing PP fibers to Bangladesh. Polypropylene (PP) fibers are synthetic fibers strategically mixed into concrete. These short, chopped fibers offer a surprising array of benefits:

- Crack Minimization: PP fibers don’t prevent cracks entirely, but they act like microscopic bridges, holding the concrete together and minimizing crack size. This significantly reduces the entry points for water, salt, and harmful chemicals, extending the lifespan of the concrete structure in Bangladesh’s challenging environment.

- Lightweight Champion: Compared to steel, PP fibers are significantly lighter. This translates to easier transportation, handling, and potentially reduced construction costs, making them ideal for large-scale projects.

- Design Flexibility: Unlike bulky rebar, PP fibers offer greater design freedom. They are ideal for intricate architectural elements or thin concrete applications where traditional rebar might be impractical. This opens doors for innovative and aesthetically pleasing structures to grace the Bangladeshi skyline.

Cost Considerations: Striking a Balance

While PP fibers offer numerous advantages, they aren’t a one-size-fits-all solution. Here’s a breakdown of the pricing comparison to consider:

- Steel Rebar: Prices fluctuate based on market demands and material costs. However, as a well-established material, rebar often enjoys a more stable price point.

- PP Fibers: The cost of PP fibers can vary depending on the fiber length, type, and desired dosage. Generally, incorporating PP fibers increases the concrete cost by 10-15%.

The Verdict: When PP Fibers Shine

PP fibers are not a direct replacement for steel rebar in every scenario. However, they excel in specific situations, making them a valuable addition to Bangladesh’s construction toolbox:

- Thin Slabs & Shells: For applications like concrete countertops, pavements, or architectural facades, PP fibers effectively minimize cracking and offer design flexibility, perfect for the growing demand for modern and stylish buildings in Bangladesh.

- Corrosion-Prone Environments: In areas with high humidity or salt exposure, such as coastal regions, PP fibers’ resistance to corrosion makes them a valuable alternative to rust-prone steel rebar. This ensures the longevity of structures in Bangladesh’s diverse climate.

- Secondary Reinforcement: When used in conjunction with strategically placed rebar, PP fibers can provide additional crack control and enhance the overall strength of the concrete structure. This allows for a more efficient use of materials and potentially reduces construction costs.

Naif Engineering and Builders Ltd.: Leading the Way with PP Fiber Innovation

Naif Engineering and Builders Ltd. (NEABL) (www.neabl.com) has taken a bold step forward by being the first company to introduce PP fibers in Bangladesh. Having successfully implemented PP fibers in several projects throughout the country, they are demonstrating the real-world benefits of this revolutionary material. This paves the way for a new era of sustainable, durable, and visually stunning concrete structures in Bangladesh.

The Final Word: A Brighter Future for Bangladesh’s Construction Industry

PP fibers represent a significant advancement in concrete reinforcement. While they might not replace rebar entirely, they offer a lighter, more versatile option for specific applications. By understanding their advantages, limitations, and cost considerations, engineers, architects, and construction professionals across Bangladesh can make informed decisions, pushing the boundaries of concrete design and construction. This paves the way for a future where Bangladesh’s built environment is not only strong and functional but also innovative and aesthetically pleasing.