Technical Excellence: Precision Engineering for High-Volume Operations

This level of flatness is non-negotiable for facilities like the Ispahani Tea Factory, where Material Handling Equipment (MHE) operates at significant heights and speeds. A truly Super-flat Floor ensures:

- Maximum Safety: Reduced sway and vibration for forklifts operating at high levels.

- Operational Efficiency: Faster travel speeds and reduced cycle times for MHE.

- Lower Maintenance Costs: Less wear and tear on the MHE, tires, and the floor itself.

The Power of TOP-100 Floor Hardener

To achieve the required durability and longevity for this high-traffic environment, we incorporated the supply and application of TOP-100 Floor Hardener. This high-quality, dry-shake hardener creates a dense, non-dusting surface that is significantly more resistant to abrasion than standard concrete. As a specialized Floor Finisher, this application ensures the floor can withstand the constant movement of heavy loads and maintain its integrity for decades.

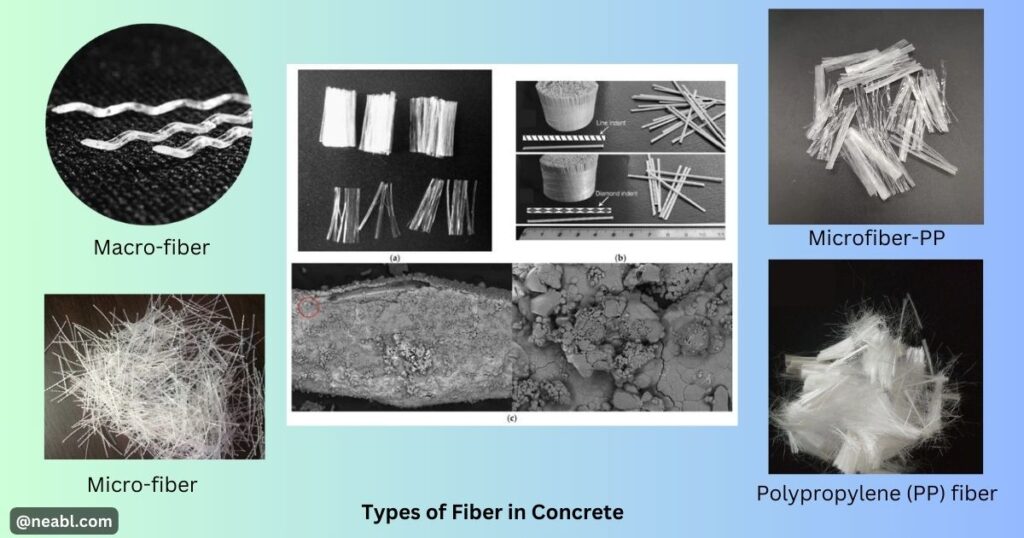

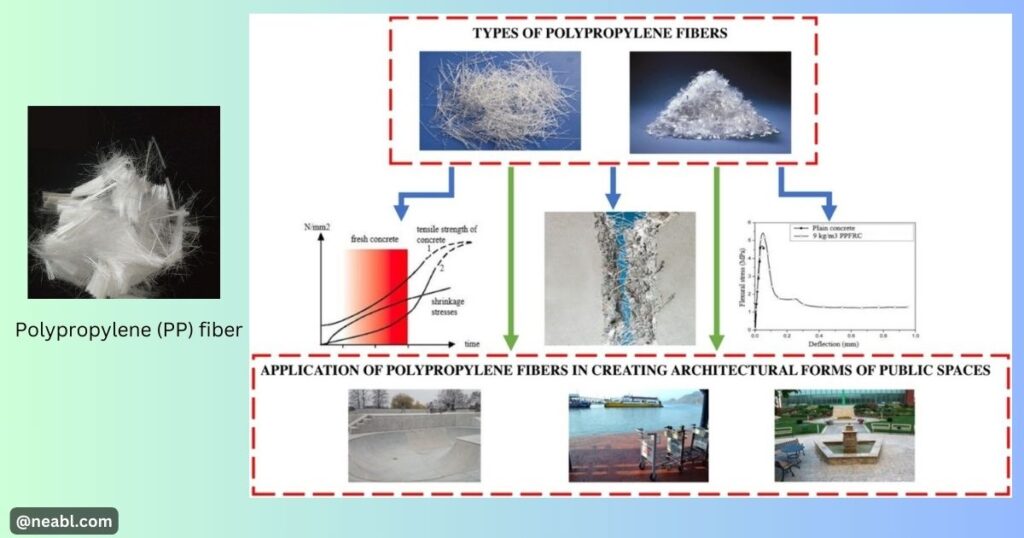

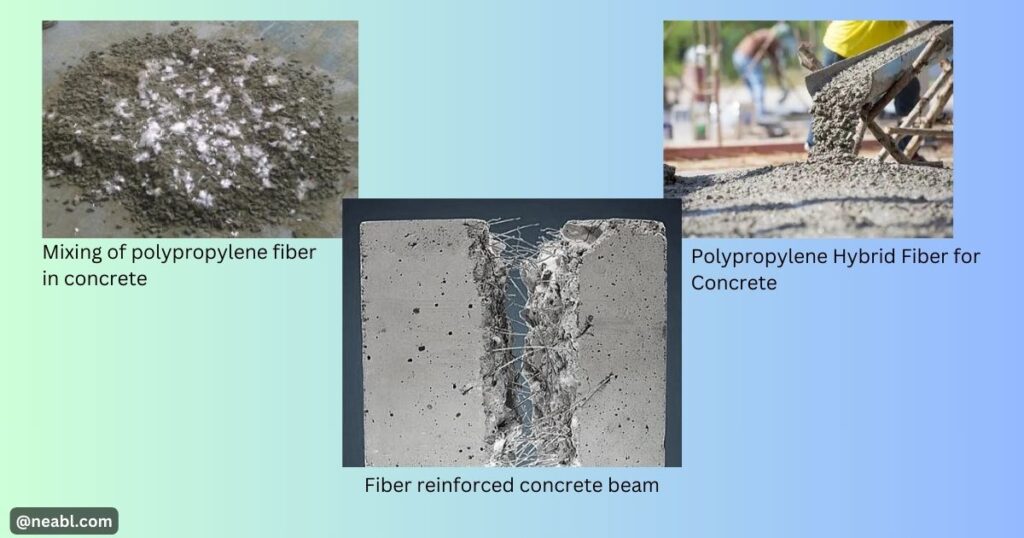

Key Innovation: The Macro PP Fiber Advantage

- Enhanced Crack Resistance: It effectively controls plastic shrinkage and long-term drying shrinkage cracks, which are common failure points in large industrial slabs.

- Corrosion-Free Durability: Crucial for a food-grade facility like a tea factory, the synthetic fiber eliminates the risk of corrosion and spalling associated with steel.

- Increased Toughness: The fibers improve the concrete’s post-crack performance and fatigue resistance, ensuring the floor remains robust under constant, heavy use.

Building Green: The LEED-Certified Factory

Naif Engineering’s role in delivering a high-quality, long-life DM-1 Super-flat floor in Bangladesh contributes directly to the factory’s sustainability profile. A floor that requires minimal maintenance, reduces equipment wear, and is built with durable, innovative materials like Macro PP Fiber is inherently a sustainable choice. This project stands as a shining example of a LEED-certified factory in Bangladesh, demonstrating that world-class operational efficiency and environmental responsibility can go hand-in-hand.

The Naif Advantage: Your Partner for World-Standard Industrial Solutions

Our expertise in specialized industrial flooring solutions ensures that your facility is built not just for today but for the demands of tomorrow. We combine technical mastery with a deep understanding of operational requirements to deliver floors that are faster, safer, and more cost-effective to run.

নতুন বছর নতুন উদ্যমের সঙ্গে শুরু হোক, পুরনো হতাশা ভুলে গিয়ে নতুন করে শুরু হোক যাত্রা। শুভ নববর্ষ।

Let the new year begin with new enthusiasm, forget the old disappointments and start the journey anew. Bangla Happy New Year 2024 (Poila Baishakh 1431).

#BanglaNewYear #NaifEngineeringBuilders #PohelaBoishakh #Celebration #SpreadLove #NaifGroup